Industrial Concrete Finishing

March 21st, 2024 at 11:43 am

An area that Concrete Polishing are thrilled to be venturing into this year is Industrial Concrete Finishing. We have a team…

August 5th, 2019 at 9:24 am

A properly placed and finished concrete floor installation makes polishing stages quicker and more effective. Concrete floor installation takes experience and careful planning. It is also important to decide on the right design mix. And the combination of products. A floor we installed in Stoke in July 2019 shows how these factors can combine to make a beautiful floor. Which will be ready to polish after curing.

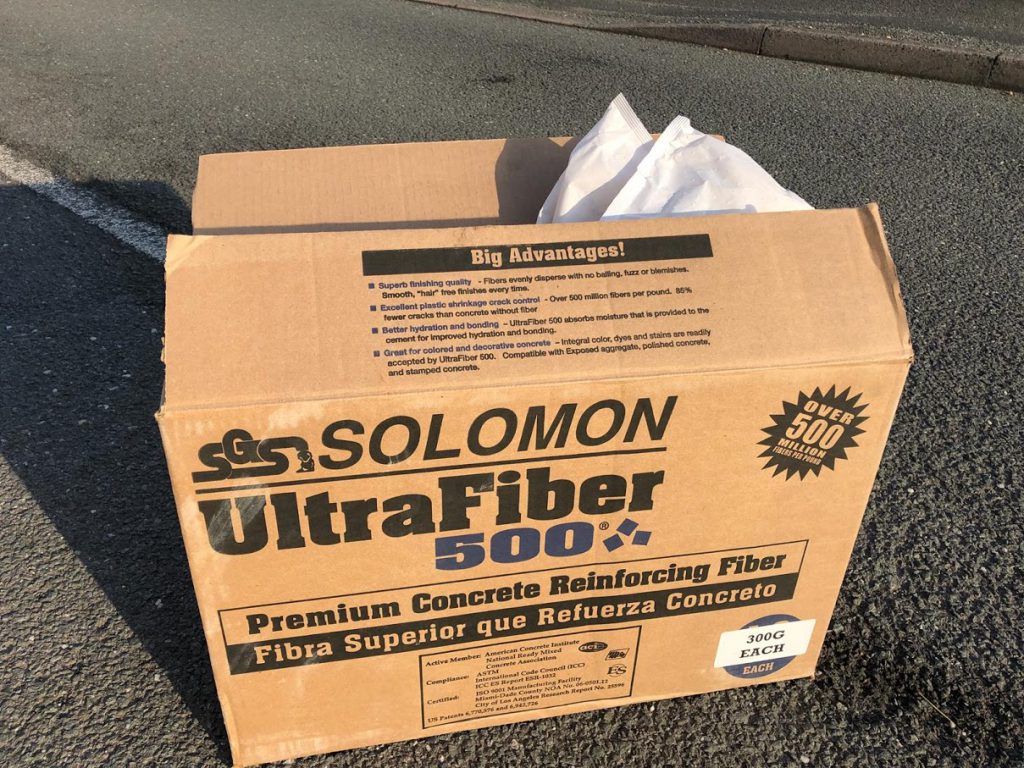

To minimize the chance of cracking, contractors placed fibers in the mix design. Using a cellulose-based fibre, UltraFiber 500 does not pose the risk of balling and fuzzing how polypropylene fibres can. It also absorbers in colour. So the floor can be integrally coloured or dyed. On this occasion, we used a Silver Grey colour surface hardener. The hardener was applied after the contractors had placed the concrete. This product also helps to harden the surface, which is, therefore, able to take the pressure of the polishing stages.

The floor was being placed on one of the hottest days of the year, so extra care had to be taken. Concrete laid in very hot conditions will often hydrate too quickly, which can lead to cracks forming as water bleeds out and the concrete shrinks too rapidly. Spraying water on the slab can offset this issue, but that in turn weakens the surface of the concrete. To help achieve the floor the client was looking for we applied a finishing agent, DAY1, instead of water. This extends the concrete’s workability time, helps protect it from drying too quickly and also adds further strength to the concrete.

As the images below demonstrate, a power trowel can be used to create a smooth, sealed slab. This is the ideal surface to create a rustic or industrial style floor from. Power floating helps to keep the aggregates to the lower part of the slab, reducing the chance of exposing them during polishing.

Adding the fibres, surface colour, and finishing aid allowed us to achieve a fantastic finish on what proved to be the hottest day on record. What brought the floor together was the skill and experience of our team. Placing decorative concrete is a complex process involving a high degree of care and judgment. The high quality of the floor is visible from the images on this page and is a testament to our staff’s commitment to quality polished concrete floors.

March 21st, 2024 at 11:43 am

An area that Concrete Polishing are thrilled to be venturing into this year is Industrial Concrete Finishing. We have a team…

January 29th, 2024 at 5:04 pm

Polished concrete is considered an Eco-friendly flooring choice. In the majority of cases concrete is made up of natural ingredients. The…